Week 4: Update

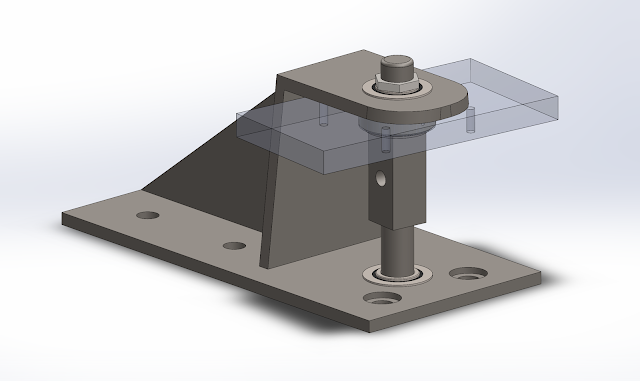

Figure: Shaft being prepared on the Lathe. The week before we got our raw materials into the laser cutting shop to get it cut into the parts that are needed. The water jet at school was broken, so we had to find a third party to cut our parts for us. While these parts are being cut, I worked on the shaft that will go into the rotary part of the bogie. I used the Lathe to carve up a shaft to our specifications and we were able to successfully get it done in the shop itself. On Tuesday we got our parts in, along with the parts for the other teams. Due to some miscommunication from the vendor, we didn't get some of the parts to our specification. Now we are tasked to work with the parts which we are given with in order to get it to the right specifications. We are currently using a hole screw to enlarge the size of the hole for the thrust bearing. We tried the whole day to do that with a milling machine but no progress was made. With the help of Prof. Furman, we are going to the